Smart Runner & 3D Gating

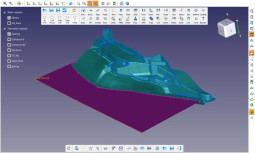

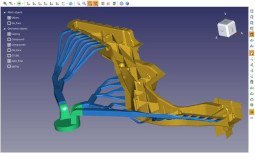

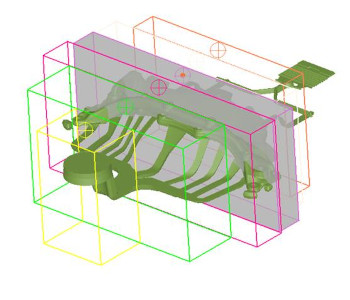

3D die face design (ParaCAD)

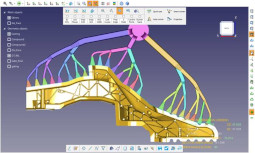

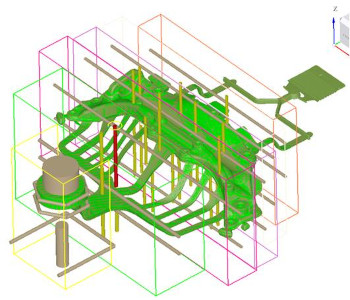

Design gating system in a workspace (SmartRunner)

Designed runner system in a workspace (plan)

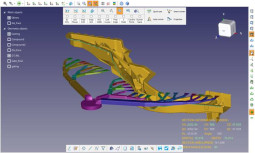

Projected CAD base 3D runner

SmartRunner is a breakthrough technology in Cast-Designer, which build-in the last self-learning AI technology.

With SmartRunner, the system can generate the runner layout and topology automatically.

Even if for complex 3D runner system, the Cast-Designer system can handle it easily.

- Define the work space and create the 3D die face and addendum in ParaCAD, the build-in CAD system.

- Design the flat runner system in SmartRunner function.

- Check the inner gate size and distribution in QucikCast with the gate projection function.

- Generate the runner system in SmartRunner and make some modification manually (if any).

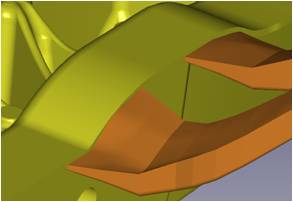

- Using 3D runner projection function to get the CAD base 3D runner system.

The generated 3D runner system (inner gate)

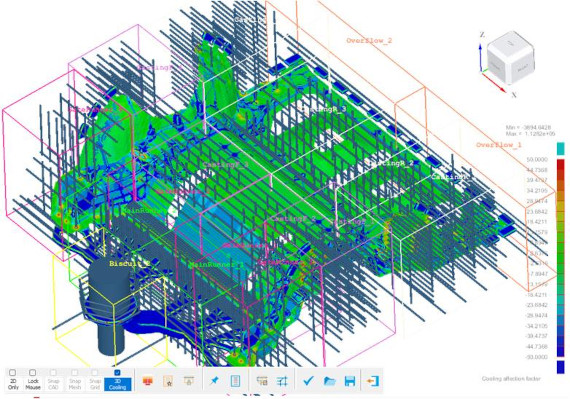

Smart Cooling

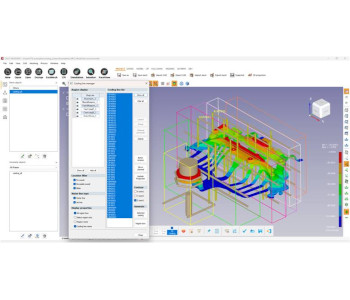

Cooling system for GigaCast mould

SmartCooling automates the key system of die casting, cooling design, by adopting a three-step method to ensure a comprehensive and optimized cooling system design, and speeds up the cooling design process by 10 to 30 times.

Step-1: Base on the metal flow path, assign the region and sub-region to the casting part (includes the gating & overflow system). Six main regions and 24 sub-regions are supported in the system. The casting volume and projection area will be distributed to each sub-region.

Step-2: Provides the basic information such as the casting and mould material, as well as the production rate and cooling channel properties. The system will predict the cooling system then make the layout automatically. This is the core technology of the SmartCooling.

Step-3: The user can make any modification of the designed cooling channel base on the experience and knowledge. The system also integrated the fast cooling function to make quick cooling system evaluation. All location adjustment by user will be feedbacked by the fast cooling immediately.