Semi-Solid Modeling Simulation

Typically, all semi-solid metal casting processes have critical small process windows, so mould concept and layout of the casting process have to be developed much more accurately than in 'normal' metal casting.

Cast-Designer could be used for several various physics of semi-solid modeling with different numerical models, such as non-Newtonian flow.

Several material models are used in Cast-Designer for semi-solid casting and thixo-moulding

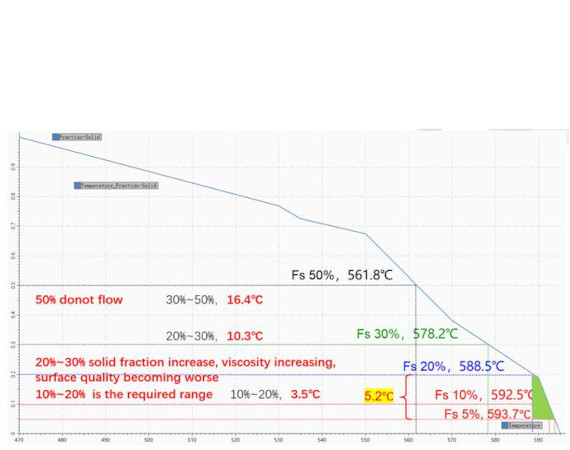

Low solid fraction semi-solid casting of magnesium alloy. Control the temperature is the key point of the process, the high-quality production windows is only 10 C degrees. The defects of poor surface filling are mainly caused by unreasonable temperature and solid fraction.

Thixo-Moulding model (Flow simulation)

The semi-solid module could be used for

- What are the right casting temperature, fraction solid and flow velocity?

- What are the suitable mold tempering approaches?

- How do melt viscosities, flow velocities, local fraction solids and local temperatures of the melt develop during filling?