Cast-Designer

End to end solution for casting business

CAST-DESIGNER OVERVIEW

C3P Engineering Software International Co., LTD has developed a software namely Cast-Designer, which is specially designed for Casting business. The Cast-Designer software has more than 50 years of industry experience to provide end-to-end solution for foundry industry, ranging from metal charging, DFM analysis, step-by-step guidance in gating system design, advanced thermal, flow, solidification and stress simulations and artificial intelligent based automatic optimization.

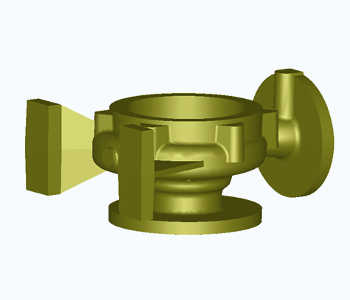

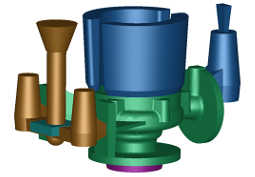

3D Casting part

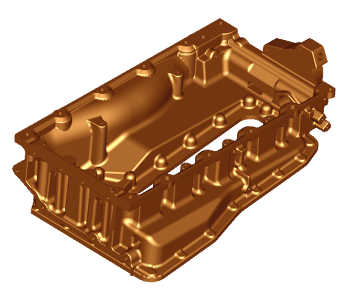

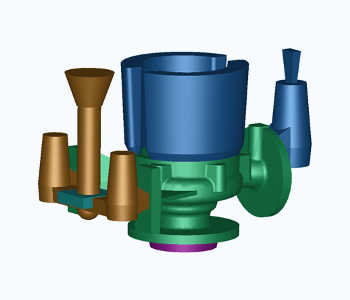

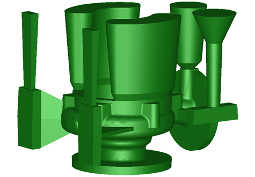

Gating system design

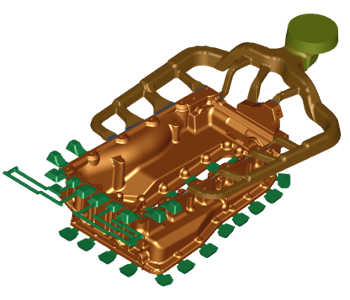

Process analysis & optimization

The Cast-Designer software supports all major foundry processes and predicts the casting defects like shrinkage porosity, air entrainments, surface defects, residual stresses, distortions etc. The Software Helps foundry engineers to make right decisions early in the design stage of casting system development and to improve quality & yield ultimately reduce the manufacturing cost. It can also help the industry to achieve the target of 'Time to Market', 'Quality to Market' and remain 'Competitive'.

3D Casting part

Gating system design

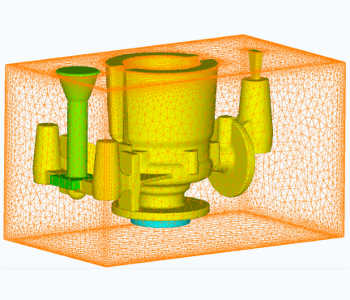

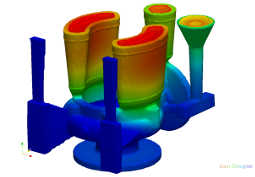

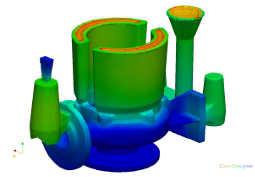

CAE Modeling

The Cast-Designer software is a quick casting design and analysis tool which is based on Upfront Design and Analysis Technology. The core of Upfront Design and Analysis Technology is to allow engineers to conduct fluid flow, heat transfer and solidification analysis with the assistance of combination of expert system and CAE technology. So that it helps engineers to make a Right decision in the early design stage of a project. The Upfront design & analysis technology have already been becoming a very important role in main stream design process.

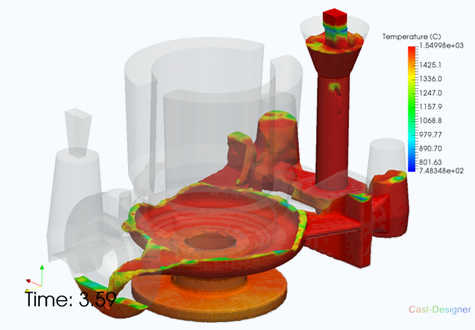

Flow simulation

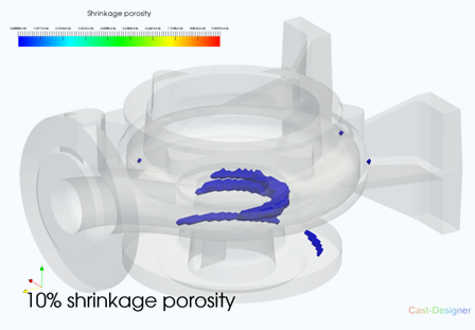

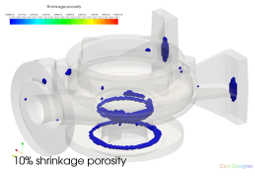

Shrinkage porosity

DESIGN PLAN EVALUATION

The Cast-Designer provides a powerful tool to evaluate different design plans in fast and easy way.

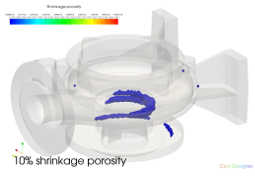

For example, the existed casting part was steel with 23.5Kg, two design plans were studied.

PLAN-A

With 27.2Kg riser and the solidification time was 853 sec, the final shrinkage porosity volume was 20.51 cm^3.

PLAN-A

Flow result (A)

Solidification result (A)

Shrinkage porosity (A)

PLAN-B

With 26.2Kg riser and the solidification time was 404 sec only, the final shrinkage porosity volume was 4.17 cm^3.

PLAN-B

Flow result (B)

Solidification result (B)

Shrinkage porosity (B)

So, with the Cast-Designer Software, the users can optimize a casting design by detecting the part features with potential flow and solidification problems as well as evaluating difference casting systems in the early design stage. Even a novel with limited experience in simulation who can easier to undertake the design, setup in a very short period of time.