Part Ejection Simulation

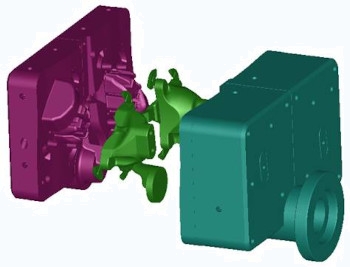

The quality of parts produced by die casting may be affected during the ejection stage of the production cycle. At this stage the parts are mechanically forced to separate from the mould surfaces.

The ejection force depends on the shrinkage of the metal alloy onto the core and on the friction properties of the contacting surfaces at the moment of extraction.

Ejection takes place in a very short time, hence the static coefficient of friction must be considered for modelling the ejection process.

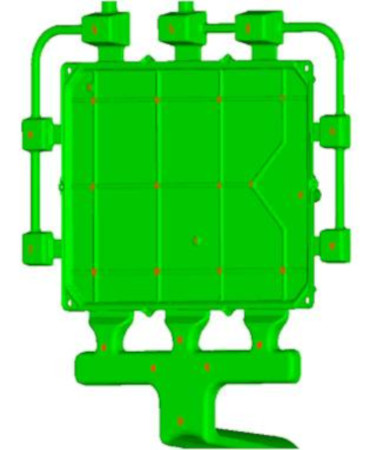

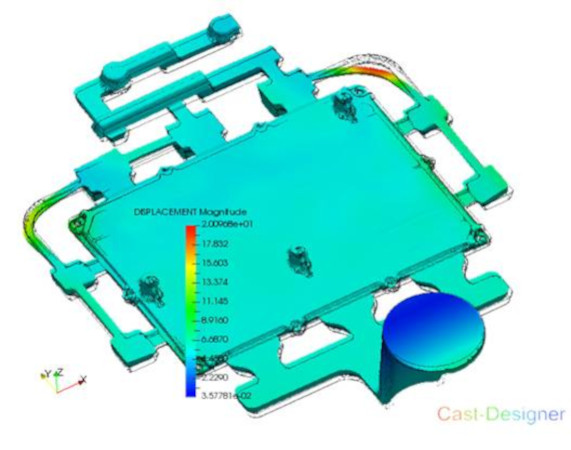

The ejection pin location and the part distortion after ejection. The simulation coupled the full mould temperature and die contact force.

Part ejection simulation:

- Perform a full mould stress simulation: Solidification + Stress simulation, full mould or solid shell model, take account the contact pressure.

- Couple to Cast-Works/CDPE for ejection process simulation. The following result will be taken: ejection time, casting temperature, residual stress of casting and contact pressure of casting.

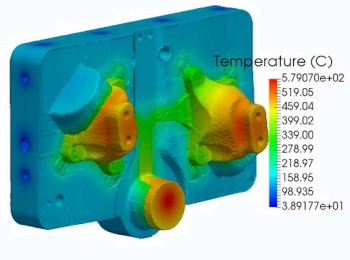

The whole die sets and temperature of ejection