KBE for Sheet Metal Stamping

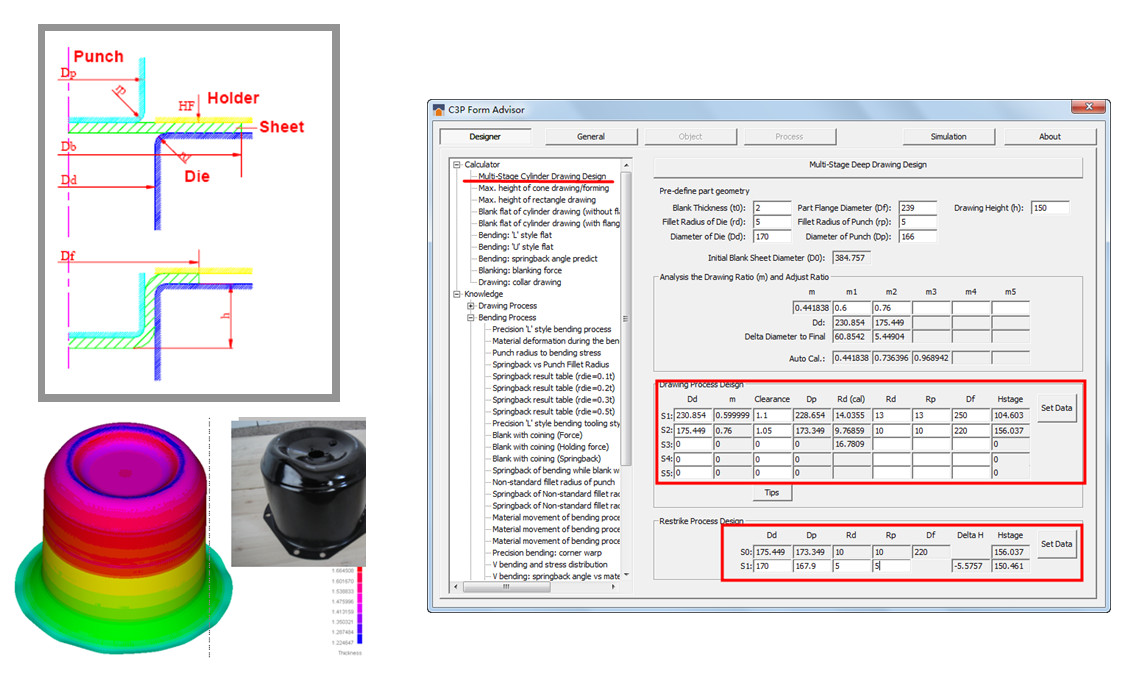

- AI-FORM’s KBE (Knowledge-Based Engineering) has developed many special KBE applications which help die designers to find a quick way to carry out part and die design.

- Based on feature technology, features have been extracted and represented by the object-oriented method. Stamping features and their parameters have been defined and extracted based on feature technology and stamping process rules. The whole product knowledge has been represented by frames that directly map to objects (or features) in the object-oriented sense.

- Based on Knowledge-Based Engineering techniques, AI-FORM provides an initial assessment of manufacturing feasibility. KBE is also a powerful tool to use during the design process to ensure that the design is right at the first time.

AI-FORM's KBE system to guide the multi-stage deep drawing design

Stamping Feature Study

- It is well known that stamping parts are combined with a couple of stamping features, such as piercing, bending, blanking, drawing and forming, half-cut, ironing, coining, burring, strength, etc.

- The relationship between features is like a tree; some features are combined by sub-features. If all the features can be mastered well, it is much easy to control the full part to achieve the requirement.

- Unfortunately, the detailed study of the stamping features, special to high precision products and progressive die, is still a bottleneck problem in the real industry and the knowledge of these features were still too insufficient. Up till now, many “know-how” still exist in this field. The numerical simulation provides an effective way for feature study, the parameters could be changed very easily and the final result could be summarized as the company in-house design guide or standard.

- This module can provide a faster and simple way to generate the basic feature model (both CAD and Analysis model) and define the simulation condition automatically. Then the user can simply change some key parameters to obtain the best result or find the balance between condition and result, and apply such design and result in the global model or die design directly. In general, it is a very economical way for both simulation and design.

KBE data of piercing and shaving process

KBE data of 90-degree precision bending and Springback result

Pre-defined feature design template

Predefined Templates

AI-FORM's KBE offers predefined templates covering bending, forming, drawing and stretching. The user can also make customizations based on these default templates by modifying its geometry and feature parameters.

KBE Data Customization

AI-FORM's KBE system is an open system, the user can easily add unlimited user’s data. Simply edit the XML template, the user can add more classes and sub-classes to the KBE system.